During the working day, an operator is exposed to numerous vibrations while using the vehicles for the range of tasks that are carried out in the mining operation (transport, loading, hauling of ore, etc.). These vibrations can be harmful to the human body and can lead to injuries of different severity.

TORSA’s vibration monitor allows real-time analysis of human exposure to vibrations and is capable of immediately alerting when the safety levels established by international regulations (UNE ISO 8041 / ISO 2631-1) are exceeded.

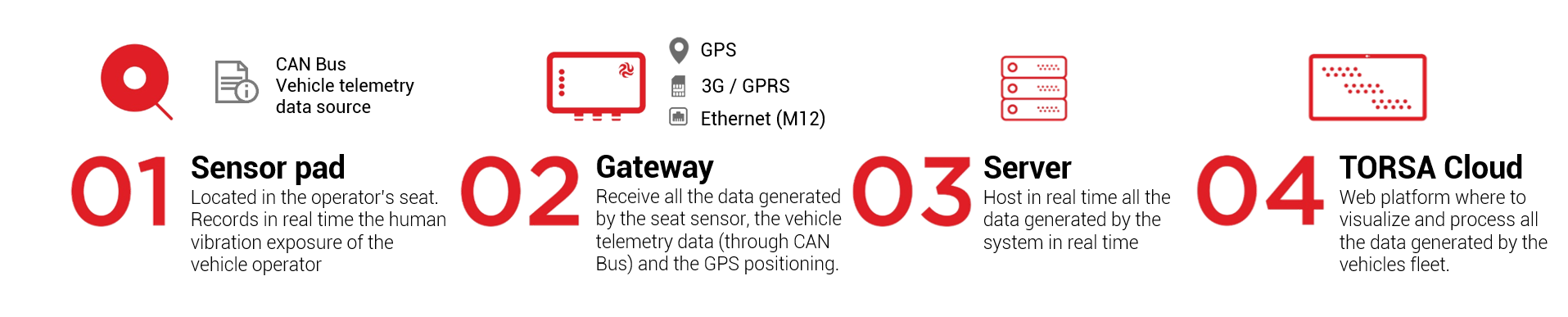

Vibration data is collected by a sensor pad located in the operator’s seat. This information is sent in real time to the communications gateway and from there to a server where the information is centralized for viewing through the TORSA Cloud platform thus ensuring the correct interaction, operation and technical information management for all our clients.

Compliance with international regulations and the allocation of a unique ISO 8041 compliance certification document for each system manufactured, ensures this data is considered complete and valid by any type of audit or legal procedure. This certification is carried out by an external and ENAC accredited laboratory.

After the development and implementation of TORSA’s vibration monitoring system in the mining operation’s fleet of vehicles, the following benefits have been observed for the different mine areas:

Decrease in operator injury: By monitoring the vibrations in real time and continuously, it is possible to analyze the serious injuries or “lashes” reported, which in turn enables the identification of those workers who need preventive training.

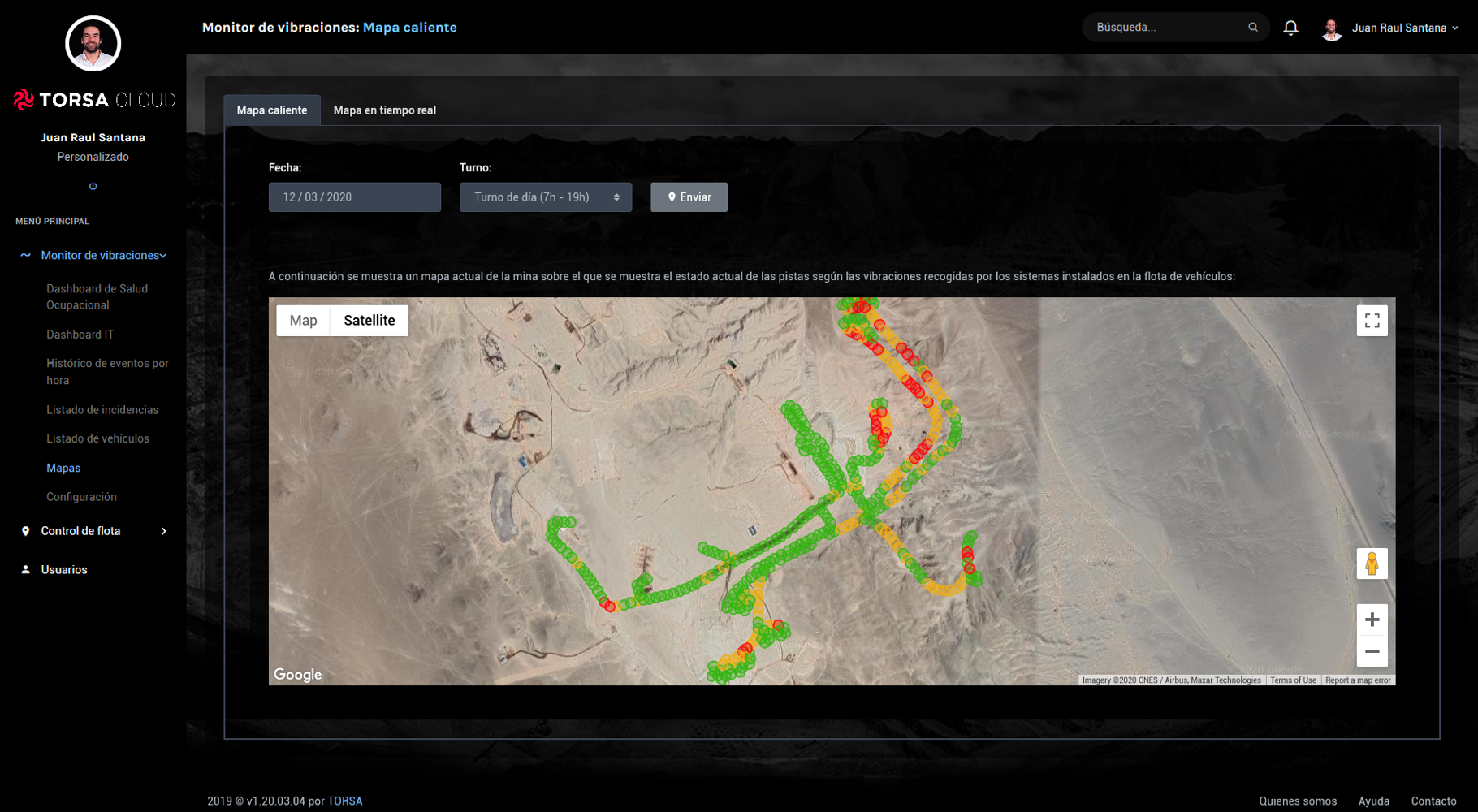

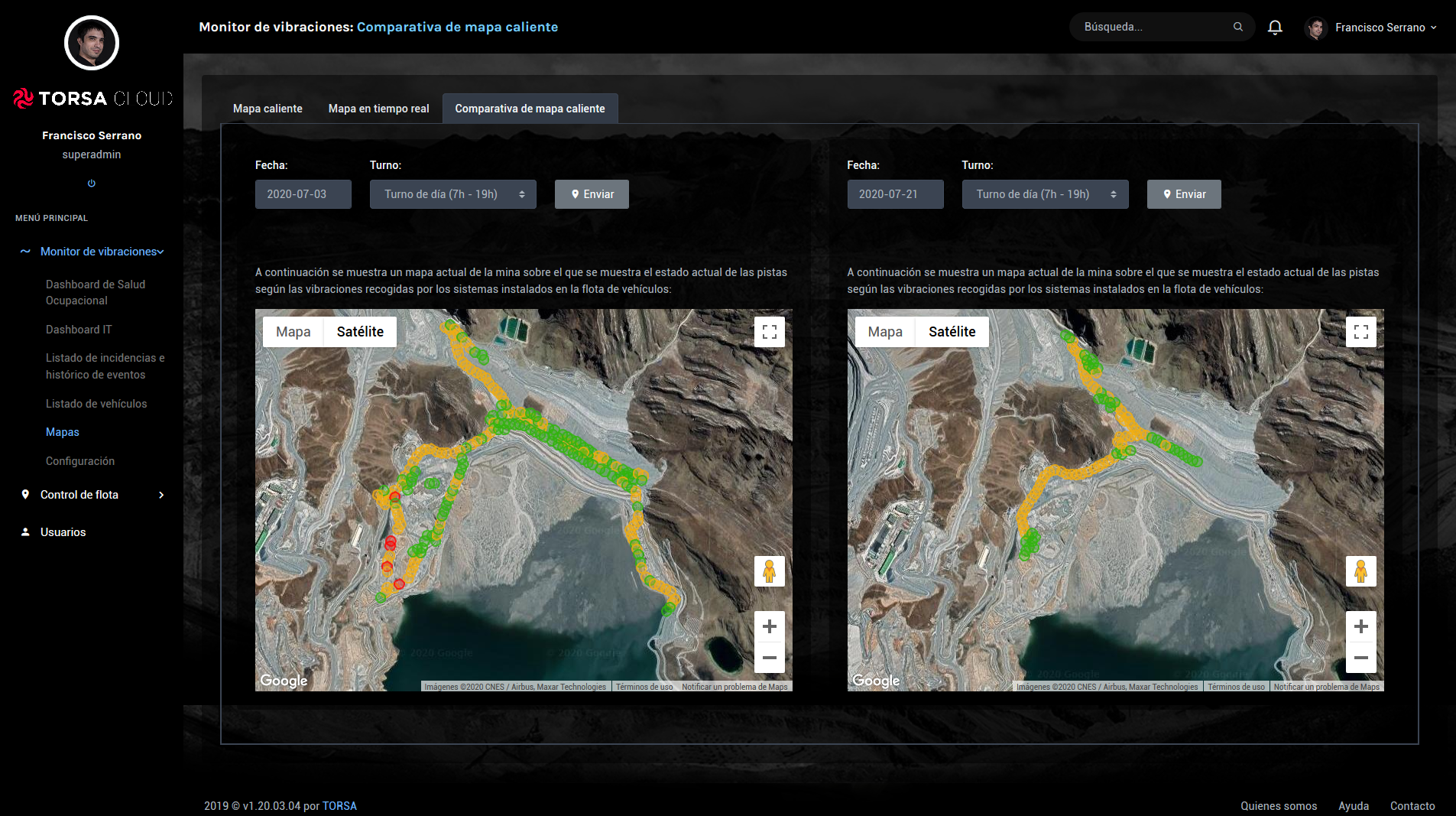

Analysis of the state of the mine tracks: Applying vibration fusion algorithms with the coordinates of its integrated GPS, hot maps of the mining operation are generated with the real-time status of the tracks as a tool to be used by the maintenance department.