Critical challenges at one of the world’s largest mines

Antamina, one of the world’s leading producers of copper and zinc concentrates, operates in the challenging environment of the Peruvian Andes. In this context, improving operator safety, ensuring regulatory compliance, and increasing operational efficiency were not just desirable improvements—they were strategic priorities.

Before implementing Torsa’s solution, Antamina faced several operational challenges:

- Significant equipment downtime, partly due to limited visibility of haul road conditions, which hindered effective planning of predictive maintenance.

- High risk of collisions, especially in shovel-truck interaction zones and shared haul routes, endangering both personnel and equipment.

- Frequent operator absenteeism caused by injuries related to prolonged exposure to vibrations in vehicle cabins, particularly spinal injuries.

These issues imposed a substantial human, economic, and operational cost that Antamina urgently needed to address.

The consequences were far from minor. Each injury meant not only a human toll, but also a loss of experience and increased operational strain. Equipment downtime affected daily production and placed additional pressure on corrective maintenance efforts. Every incident—or near miss—on the haul roads represented an unacceptable risk in an industry governed by strict safety standards.

Antamina needed a solution that would provide real-time visibility, anticipate risks before they occurred, and deliver actionable information to support operational decisions. They were looking for a technology that could not only solve current issues, but also set a new benchmark for safety and efficiency in mining operations.

Improving mining safety through technology

With the goal of mitigating risks and optimizing operations, Antamina chose to implement two advanced solutions from Torsa:

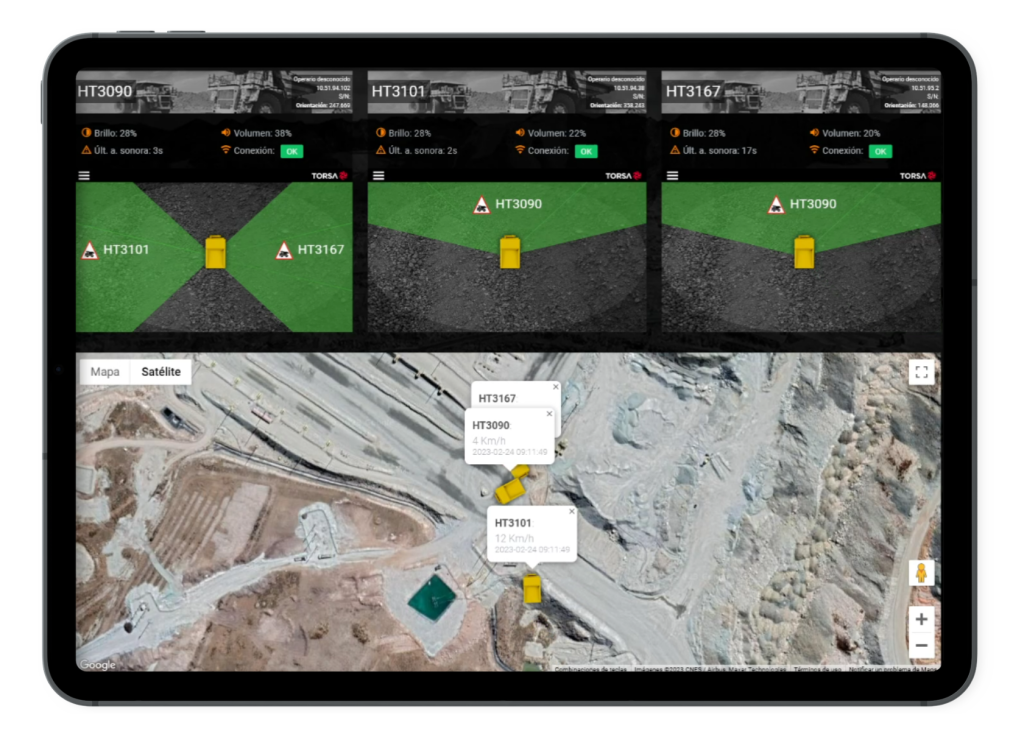

- Collision avoidance system for mining: designed to detect vehicle proximity in real time, alerting operators to hazardous situations and significantly reducing the likelihood of incidents.

- Human vibration exposure monitor: continuously records the vibrations to which operators are exposed, generating individual profiles, historical records, and heat maps of the haul routes.

Both solutions are integrated into the .torsacloud platform, where data is stored, analyzed, and transformed into actionable insights for decision-making, maintenance strategy planning, and continuous improvement.

Results that set a new standard for mining safety

The results achieved by Antamina after implementing Torsa’s solutions have been both significant and measurable:

- 100% elimination of simulated traumatic spinal injury cases. Data collected by the vibration monitoring system enabled the adjustment of routines and operational practices, completely eliminating these simulated scenarios.

- 90% reduction in hazardous shovel–truck interaction reports. Since the implementation of the collision avoidance system and through the end of 2022, incident reports dropped by 74%, and have now reached a 90% improvement.

- Continuous monitoring of operational conditions. Real-time heat maps and individual operator records are generated, enabling more effective predictive maintenance planning and extending the service life of components.

- Improved operator training and behavior. Data analysis has made it possible to identify risk patterns and deliver personalized training programs for shovel and truck operators.

- Reduced absenteeism and increased equipment availability. Improved working and operational conditions have significantly lowered absenteeism rates and equipment downtime.

- Compliance with international standards. A historical record of vibration exposure has been established, enabling compliance with international regulations and positioning Antamina as a benchmark for operational sustainability.

A model for safer, smarter mining operations

The collaboration between Antamina and Torsa demonstrates how strategic technology implementation can solve complex challenges related to safety, health, and operational efficiency in mining. The deployment of the collision avoidance system and the human vibration exposure monitor has not only reduced risks, but also improved working conditions and optimized resource use.

This case marks a turning point for one of the world’s largest mining operations and lays the groundwork for a replicable model in other sites aiming for safer, smarter, and more sustainable mining.