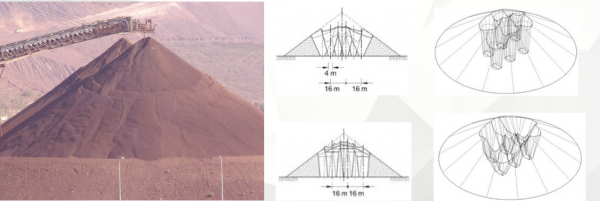

Torsa carried out a successful project to develop a state-of-the-art safety system for the stockpiles at the Antapaccay mine in Peru, owned by Glencore. The main goal of this solution was to implement an alert system for the operator at the stockpiles, aiming to prevent incidents related to the operator’s position on the absorption feeders.

Project scope:

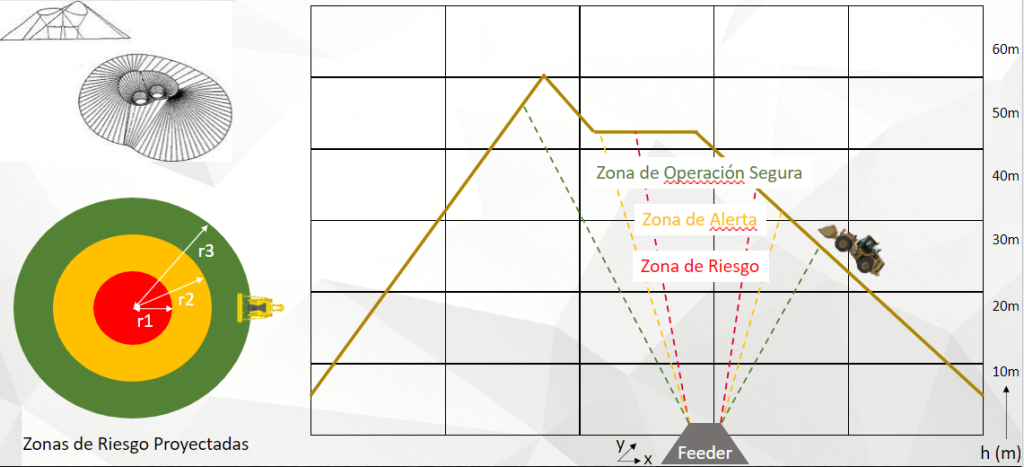

The project involved an analysis of the location of the feeders and the interaction between various mining equipment and these elements. The goal was to prevent situations where mining equipment could face setbacks during the mineral absorption process. The solution provided an easy-to-use interface that informed machinery operators of risks in their work area. It offered visual and auditory alerts only in the event of a real risk, making it an effective tool for improving safety in the work zone.

Implementation Process:

The success of the project can be attributed to the comprehensive scope of the work carried out by Torsa:

- Development of the stockpile alert solution: Torsa designed and developed the alert system based on the previously reviewed technical proposal.

Detailed engineering: Torsa carried out detailed engineering to define key data for the system’s development, including the identification of risk zones.

Equipment supply: Torsa provided the necessary equipment for the implementation of the safety system.

- Installation, commissioning, and operator training: Torsa handled the seamless installation, commissioning, and provided comprehensive training to the operators.

Achievements and recognitions:

The implementation of Torsa’s technology at the Antapaccay mine, owned by Glencore, proved to be a remarkable success. The reliability and effectiveness of the project led to Torsa’s safety solution receiving recognition from ISEM (Peruvian Institute of Mining Safety).

Differentiating factors of Torsa:

- Torsa’s experience and commitment to providing customized solutions were key to the success of the project. Some key aspects of Torsa’s technology and services include:

- Reliability and Customization: Torsa’s reputation for delivering reliable solutions, combined with its ability to design and manufacture its own products, ensured the success of the project. The safety system was tailored to meet the specific needs of the Antapaccay mine.

- Integration with the .torsacloud platform: The system communicated with the .torsacloud platform, enabling seamless connectivity and centralized monitoring. Customers could configure various types of alerts based on their specific requirements. The platform allowed access to real-time information from any internet-connected device.

Conclusion:

The successful implementation of Torsa’s safety system for the stockpiles at the Antapaccay mine highlights the company’s commitment to innovation, reliability, and customized solutions. Torsa’s ability to design, manufacture, and integrate its own technology, combined with its expertise in creating tailored solutions, was crucial in meeting the specific needs of the mining industry. The recognition received from ISEM further validates Torsa’s dedication to improving safety in the mining sector, also reflected in the leading newspaper in Peru.

ISEM awards Torsa’s technology at Antapaccay | ECONOMY | EL COMERCIO PERÚ