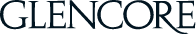

Its primary objective is to inform the machine operator about the type, position, and distance of nearby vehicles and obstacles.

Through a simple interface, the shovel operator receives information about all surrounding vehicles and objects in a non-intrusive way,with visual and acoustic alerts, triggered only when there is a real risk of collision. This makes the system a highly effective tool for reducing the risk during loading operations.

Thanks to its centimetric precision, the operator is continuously informed about whether the loading distance is appropriate or whether a collision risk is imminent.

In doing so, the system significantly reduces the likelihood of hazardous interactions between the shovel and bulldozers, haul trucks or the mining face.

As with all TORSA solutions, the high-precision proximity alert system for shovels is fully integrated into the TORSA Cloud environment, ensuring seamless interaction, reliable operation, and efficient technical data management for all our clients. TORSA works closely with the International Council on Mining and Metals (ICMM), actively participating in the Innovation for Cleaner, Safer Vehicles (ICSV) programme. This initiative brings together 27 of the world’s leading mining operators and technology providers to collaborate in a non-competitive space with the aim of accelerating the development of a new generation of mining technologies and vehicles.

Our collision avoidance system is designed to operate with control Levels 7, 8, and 9, in line with the safety guidelines and requirements defined by the ICSV programme of the ICMM and based on the definitions provided by EMESRT (Earth Moving Equipment Safety Round Table), the international entity that defines safety protocols for mining equipment.

Integrated technologies

The system incorporates the latest technologies to ensure effective protection:

- 3D LIDAR

- High-precision GPS (RTK)

- Time of Flight (ToF)

- Radiofrequency (V2V communication)

- Network communications

Awards and recognitions

TORSA, together with Compañía Minera Antamina, recently received the Technological Innovation Award from the National Society of Mining, Oil and Energy of Peru for the customised development of the high-precision collision avoidance system for shovels. The solution was recognised as a success due to the drastic reduction in equipment interaction incidents, improved safety during loading operations, and a notable increase in productivity.

Technical features

- High-precision detection (1 cm) with adjustable range according to operational needs

- Operates independently of any single technology

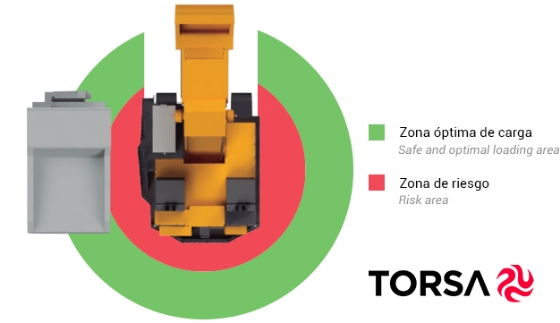

- Custom report and statistics generation

- Evaluation tool for mine training areas

- Real-time remote monitoring of active systems

- Continuous internal recording and storage of data collected and analysed by the system

- Minimal hardware required and fast installation

- Web interface via TORSA Cloud, enabling efficient and user-friendly data management

- Collision avoidance system compliant with control Levels 7, 8, and 9, following the safety protocols and requirements established under the ICMM’s ICSV programme, based on the definitions provided by EMESRT