It is an honour to provide Torsa’s solutions to Hospital 12 de Octubre and its Advanced Design and 3D Printing Technologies Unit. Your work is not only innovative but invaluable to those who benefit from your creations.

Statement from Hospital 12 de Octubre:

“Additive manufacturing activity in a hospital setting must be a safe process, just as it is in the industrial field.

The Advanced Design and 3D Printing Technologies Unit at our hospital has been implemented with a focus on the safety of professionals, as well as meeting requirements in terms of climate control, electrical safety, and chemical exposure.

Since the manufacturing process using different technologies (FDM, SLA) involves the emission of volatile organic compounds (VOCs) and ultrafine particles (UFPs), it is advisable to have an O₂ sensor capable of detecting the oxygen concentration in the fabrication room.

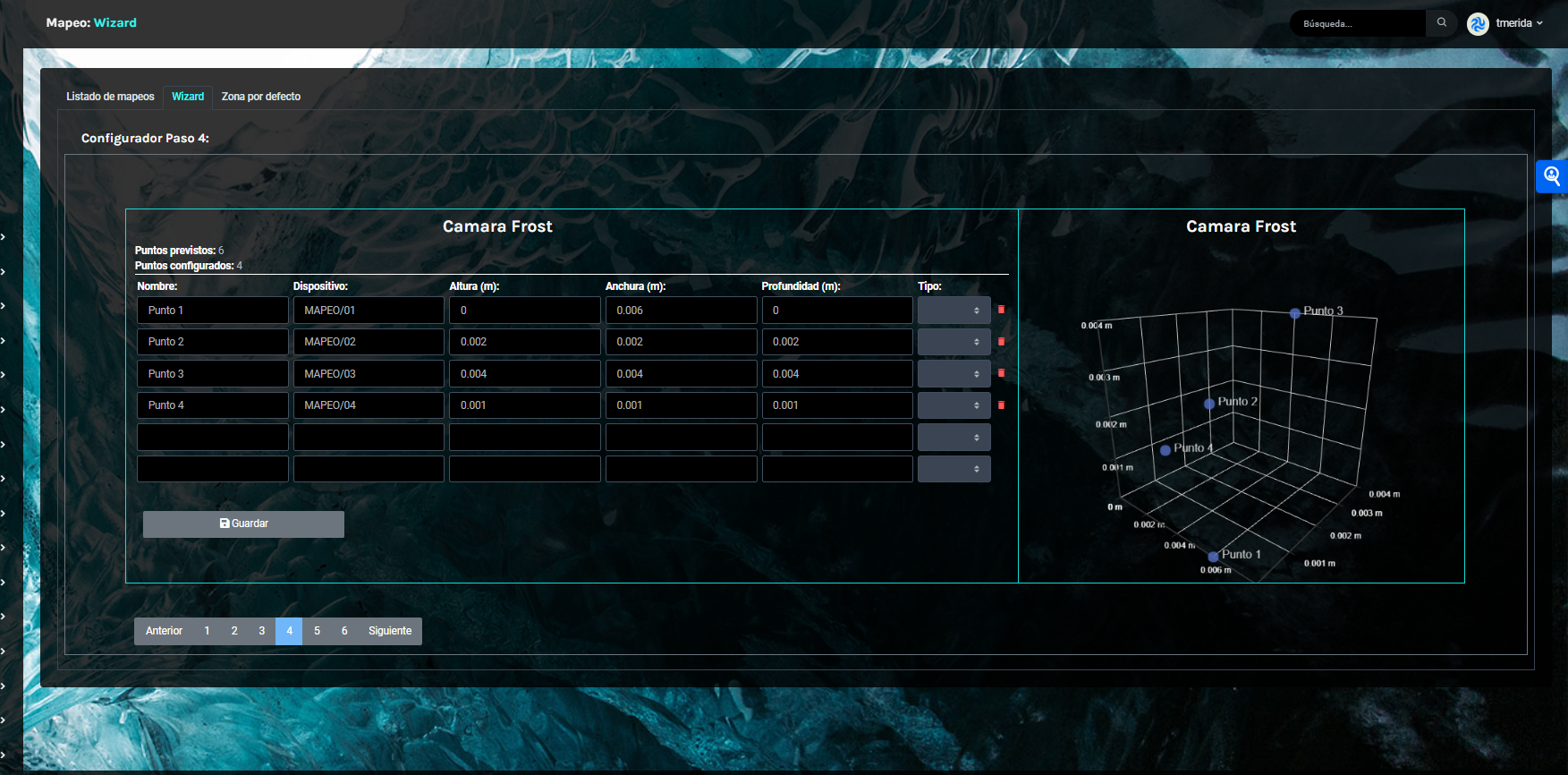

Recently, Torsa has installed a monitoring station with temperature and relative humidity logging, which also includes an O₂ sensor. This monitoring will allow us to keep records of these three parameters, two of which are required for the implementation of the quality management system under ISO 13485. This monitoring station has been exclusively designed for UTADI3D, and is named 12O.

We are proud to be the first 3D printing unit in a Spanish hospital to have this technology. We would like to thank Fernando Alfageme Fuertes for his involvement in the project and for facilitating its installation and commissioning.”