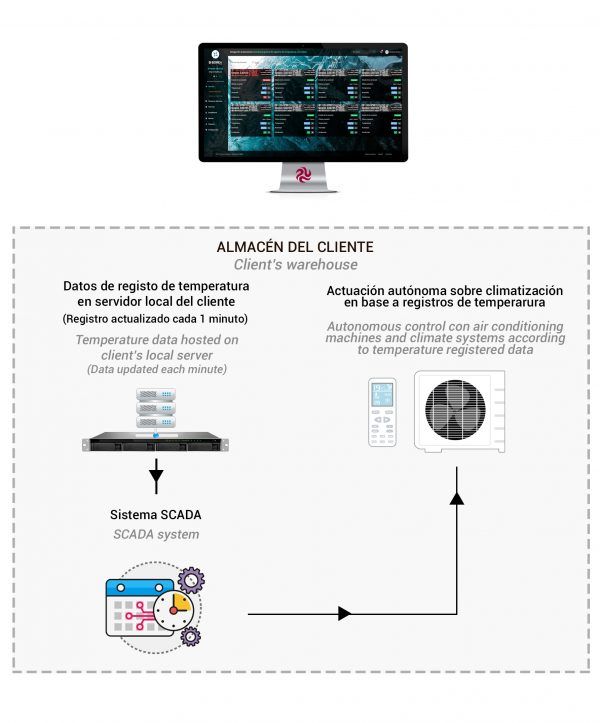

TORSA GLOBAL’s Borea system has several sensors, including temperature and humidity, making its connection to a SCADA system the best way to save costs and reduce the carbon footprint.

How?

Process control and optimization: Borea sensors connected to a SCADA system can monitor and – in an industrial process/place. This allows for adjusting operational parameters to maintain temperatures within optimal ranges and . Optimizing process temperatures can lead to increased efficiency and cost reduction.

Fault detection and prevention: Borea sensors, along with the SCADA system, can help detect unusual deviations or fluctuations in temperatures. If a problem such as a sudden temperature increase or drastic drop is detected, , preventing costly damage to equipment or products.

Energy savings: By monitoring temperatures in real-time, the SCADA system can identify energy inefficiencies. For example, , . This can result in significant long-term savings in electricity or fuel costs.

Predictive maintenance: Borea sensors connected to the SCADA system can provide continuous data on the thermal performance of equipment. This allows monitoring wear and performance of temperature-related components. By utilizing advanced analytics, the system from TORSA GLOBAL , .

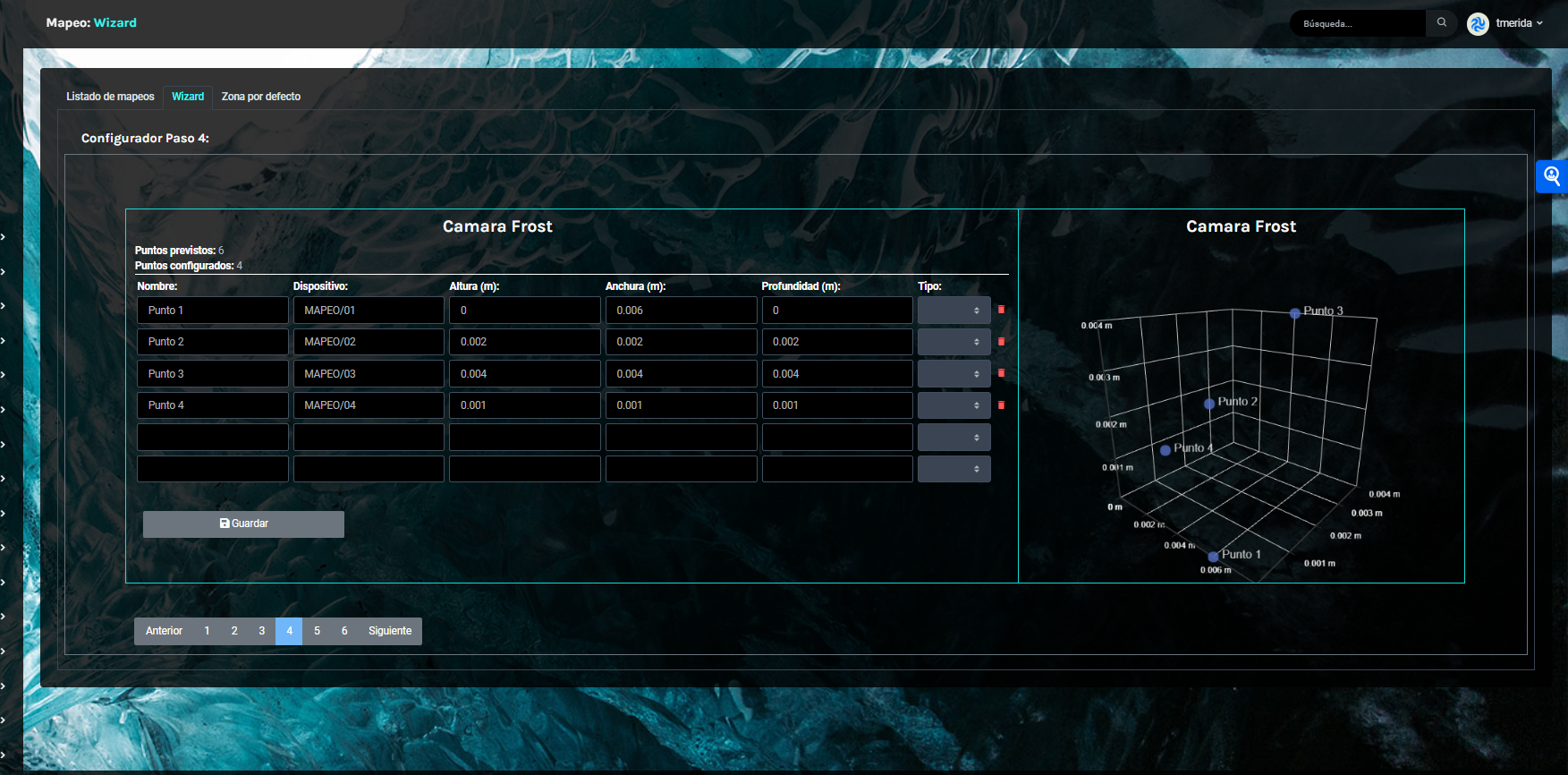

Like many others solutions from TORSA GLOBAL, the system reports to the

which can be accessed in real time from any device.

If you want to know how TORSA GLOBAL is already helping companies to save costs and reduce their carbon footprint, – @ . .