Good Practices (GxP) is a set of standards and guidelines designed to ensure the quality, safety, and efficacy of products and services in regulated industries, such as pharmaceuticals, food, and medical devices. The importance of complying with GxP lies in protecting public health by ensuring that products are manufactured, stored, distributed, and used consistently and in accordance with internationally recognized standards.

GxPs were developed starting in the 1960s as a response to the need to establish strict regulations and sound practices in these industries after historic cases of defective products causing harm to consumers or failures in medical treatments.

The Food and Drug Administration (FDA) initially set the GxP standards. This term encompasses a vital regulatory framework that encompasses multiple aspects of product manufacturing, storage, testing, and distribution. The “G” stands for Good Practices, while the “xP” can refer to various types of quality practices, such as Good Manufacturing Practices (GMP), Good Distribution Practices (GDP), Good Laboratory Practices (GLP) and Good Clinical Practices (GCP).

Effective implementation of GxP regulations is critical to obtaining regulatory approvals, maintaining consumer trust, and ensuring ethical and legal compliance at all stages of the product lifecycle.

Key elements of Good Practices GxP compliance

Good Manufacturing Practices (GMP): These regulations focus on ensuring that products are manufactured under controlled and consistent conditions, following quality and safety standards. This ranges from the design and construction of facilities to the cleaning, production, packaging, labelling and storage processes. The goal is to prevent errors and defects in the manufacturing process that could compromise the safety and efficacy of the final product. When it comes to pharmaceutical manufacturers, they must comply with Good Distribution Practices (GDP) if they are responsible for distributing their products. This includes complying with product storage and transport requirements in line with Good Manufacturing Practices (GMP) and ensuring safety throughout the supply chain.

Good Clinical Practice (GCP): This set of ethical and scientific standards ensures the protection of the rights, safety, and well-being of trial subjects, as well as the reliability and credibility of the data from these clinical trials. These GCPs include ethical standards to be followed in the process of designing, conducting, registering, and reporting clinical trials. In addition, these practices are strictly complied with so that the regulatory authorities accept the results obtained from the tests carried out.

Good Laboratory Practice (GLP): GLP standards define organizational processes and the conditions under which they are planned. They seek to ensure the quality and integrity of data generated in non-clinical studies on the safety and efficacy of products. These regulations are applied in research and development environments to ensure the accuracy, reliability, and reproducibility of results.

What does GxP compliance entail?

Successful implementation of Good Practices GxP requires a strong commitment from senior management to operational staff to carry out a number of practices:

Continuing Education and Training: ensure that all staff are properly trained in the GxP requirements relevant to their roles.

Rigorous Documentation: Maintain detailed and up-to-date records of activities, procedures, and controls to demonstrate compliance.

Validation and Qualification: Perform regular validations and qualifications of equipment, processes, and systems to ensure their suitability and accuracy.

Regular Audits and Reviews: Conduct internal and external audits to identify and address areas for continuous improvement.

In addition, adherence to these best practices requires organizations to focus on three fundamental aspects of their work:

- Traceability: Can an organization reconstruct the history of a product’s development?

- Accountability: Can an organization identify who contributed to product development and when they made their contribution? What did that contribution consist of?

- Data integrity: Can an organization reliably track the data generated during product development? Organizations can validate data integrity by identifying when data is generated during product development and for what purpose, tracking data throughout the entire product lifecycle, and specifying protocols to reduce or prevent data integrity violations.

How is GxP different from other types of regulatory oversight in other countries?

Each country or region may have its own regulations and standards to ensure quality and safety in the life sciences industries. These regulations may vary in terms of scope, requirements, and application. Despite regional and cultural differences, there is a global effort to harmonize certain regulations through organizations such as the World Health Organization (OMS) and the International Conference on Harmonization (ICH). These efforts seek to promote common quality and safety standards in pharmaceuticals and medical devices internationally.

Best Laboratory Practices in the United States

For example, in a clinical setting in the United States, laboratories may also be required to comply with CLIA (Clinical Laboratory Improvement Amendments). This best practice guide is regulated by the Centers for Medicare & Medicaid Services, which oversees laboratory testing and focuses specifically on ensuring the accuracy and reliability of laboratory test results. However, GxP covers a much broader set of work done by a lab than CLIA, which focuses exclusively on diagnostic testing.

Another type of accreditation that clinical laboratories may seek is the CAP (College of American Pathologists). CAP accreditation is done on a voluntary basis, but laboratories seek this accreditation to strengthen their reputation and credibility. The CAP also provides quality assurance, encourages continuous improvement, and improves the confidence of both laboratories and patients in laboratory services.

As a conclusion, it can be said that the CAP covers similar areas as GxP and CAP-accredited laboratories are considered to have achieved CLIA compliance as well.

How does GxP challenge the ELN and LIMS?

GxP presents significant challenges for Electronic Laboratory Notebooks (ELN) and Laboratory Information Management Systems (LIMS) due to the rigorous quality, security and compliance requirements they must meet in regulated environments.

Here’s how GxP can pose challenges for ELN and LIMS:

- Rigorous regulatory compliance: GxP regulations impose strict requirements for data documentation, traceability, and security in regulated environments such as pharmaceutical or biotechnology laboratories. This implies that ELNs and LIMS must meet detailed standards of quality and regulatory compliance to ensure the integrity of the data generated and stored.

- Validation and qualification: According to GxP, software used in regulated laboratories, such as ELN and LIMS, must be validated and qualified to ensure its adequacy and reliability. This involves conducting extensive testing to confirm that the systems meet regulatory requirements and operate consistently and accurately.

- Data security: GxP demands high levels of data security to protect the confidentiality, integrity, and availability of information generated in the lab. Software used in GxP environments must implement robust security controls to prevent unauthorized access and data tampering.

- Audits and ongoing compliance: Regulated laboratories are subject to regular audits to ensure compliance with GxP regulations. ELN and LIMS software must be prepared to face these audits and demonstrate that it meets established quality and security standards.

- GxP Process Integration: To comply with GxP, ELN and LIMS software must be able to integrate with other systems and processes in the lab consistently and effectively. This may include integration with quality management systems, sample management systems, and version control systems.

In summary, adopting properly validated and configured ELN and LIMS systems can help laboratories comply with GxP regulations effectively and improve the quality and efficiency of their operations.

How can we select a Good Practices GxP compliant lab software supplier?

Selecting a GxP laboratory software provider is a crucial process that requires considering several key factors, such as considering their credentials, services, and quality of documentation. In this way, we will be able to guarantee that the system meets the quality and regulatory compliance standards necessary to operate in regulated environments.

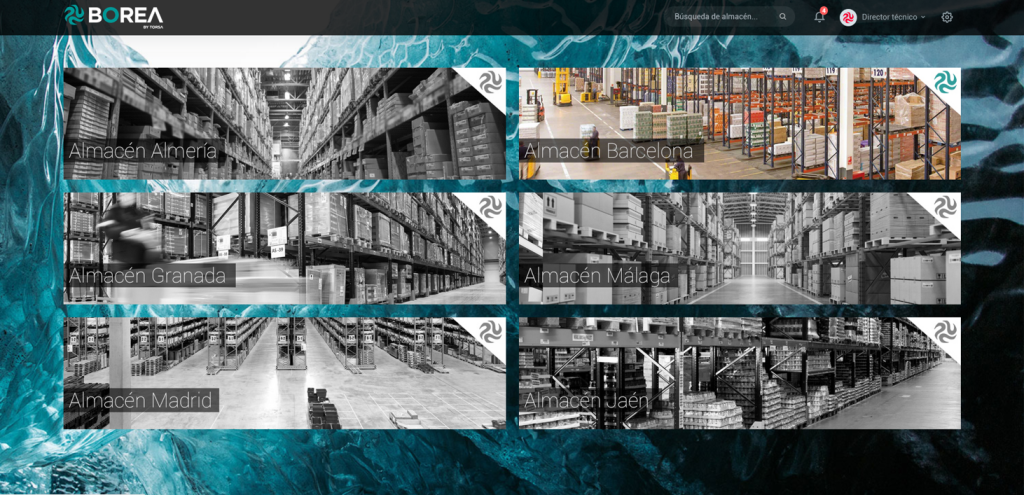

Torsa offers integrated solutions designed to meet GxP requirements in regulated environments such as the Borea System, which allows continuous recording and monitoring of temperature, humidity and gases in facilities. This system complies with all the established requirements and is in accordance with the Good Distribution Practices (GMP) established according to the ICT 155/2020 regulation and by the Good Manufacturing Practices (GMP or GMP) following the guidelines of the CFR 21 part 11 standard. In addition, our software has been developed in compliance with the ALCOA+ principles, ensuring that the data is attributable (who recorded the data and when it was recorded), readable (at the present time and in the future), contemporaneous (recorded at the time it is obtained), original (or failing that, validated copies) and accurate (they cannot contain any errors and must be accurate and precise).

Borea consists of a communications switchboard and a range of temperature and humidity sensors and recorders that are installed at critical points in the facilities to record temperature and humidity oscillation and gas control. These records are sent to a server where the information is centralized for visualization through TORSA.Cloud, the software developed by Torsa that allows the continuous monitoring of these variables.

Find out how the Borea system can boost your Good Practices GxP compliance. Fill out our contact form now to receive a personalized, no-obligation demo.

[contact-form-7 id=”783″ title=”Formulario solicitud de más información (EN)”]