A major challenge in reducing fatalities in the mining industry is improving control systems to manage the operation of mobile equipment and the transportation of people and materials. Each year, around 30-40% of industry fatalities are attributable to failures in vehicle interaction controls, and of these approximately half involve pedestrians, mostly in underground mines.

Due to the large number of fatalities and incidents in the global mining industry, the Earth Moving Equipment Safety Round Table (EMESRT) was created as a global initiative involving major companies mining. EMESRT has engaged with Original Equipment Manufacturers (OEMs) to advance the design of equipment that, beyond OEM standards, improves safe operability and maintainability.

Within the initiative promoted by EMESRT, various working groups have been created in which the main mining companies in the world have been involved, as well as equipment manufacturers (OEMs) and technology providers.

Following the need of the international mining community, TORSA, as a supplier of IoT technology and systems for the mining industry, was involved in the EMESRT working groups having the opportunity to know firsthand the existing needs in the sector and adapting its systems by adding value and meeting those needs through technology.

In addition to participating in these groups, TORSA also works closely with the International Council on Mining and Metals (ICMM) where the company is involved in the Program for Innovation for Cleaner, Safer Vehicles (ICSV), where 27 of the world’s leading companies in mining exploitation and technology supply are grouped to collaborate in a non-competitive space with the aim of accelerating the development of a new generation of mining technology and vehicles. EMESRT also plays a key role within this program by providing a complementary technical approach.

Technology as a tool to reduce accidents

Thanks to the collaborative work of the international mining community, EMESRT has carried out a project that aims to develop a standard that must be met by proximity detection systems (PDS). An interoperability protocol between third-party PDS providers and OEM-supplied equipment has been developed to establish a platform for the implementation of PDS controls in mixed equipment fleets – ISO 21815.

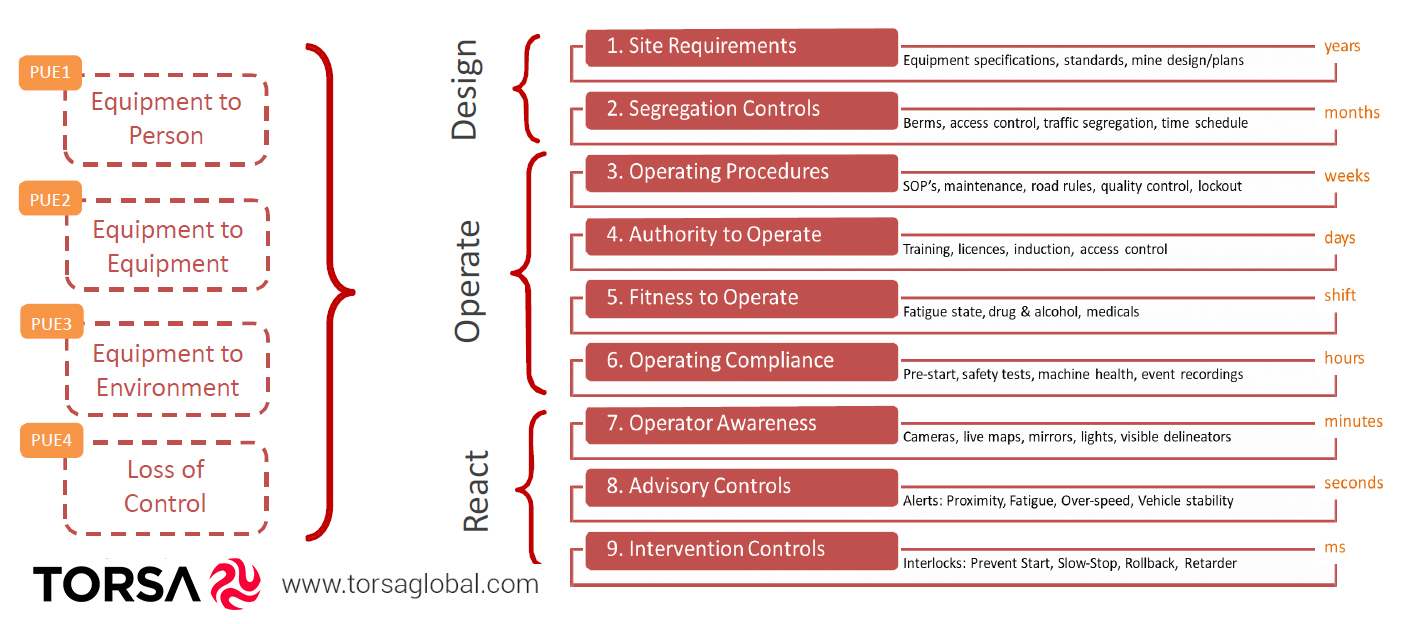

In this way, EMESRT has established various levels of incident control:

In this way, EMESRT has established various levels of incident control:

- Level 1: Site requirements: machinery specifications, mine design, standards [YEARS]

- Level 2: Segregation controls: berms, access control, traffic segregation (MONTHS)

- Level 3: Operating procedures: maintenance, traffic rules, quality control [WEEKS]

- Level 4: Authority to operate: training, qualification, licenses, induction [DAYS]

- Level 5: Physical state to operate: state of fatigue, drugs and alcohol, medications [TURN]

- Level 6: Operational compliance: safety test, pre-start, machinery status [HOURS]

- Level 7: Notice to the operator: cameras, real-time maps, mirrors, lights [MINUTES]

- Level 8: Alert controls: proximity alert, fatigue, overspeed [SECONDS]

- Level 9: Intervention controls: intervention to reduce speed, braking [MILLISECONDS]

Taking into account these incident control levels of the EMESRT, it is considered as the most appropriate requirement in the reduction of accidents that the Proximity Detection System (PDS) or Collision Avoidance Systems (CAS) perform with an Intervention Control Level 9.