In warehouse management, ensuring compliance with Good Manufacturing Practices (GMP) and Good Distribution Practices (GDP) is crucial, especially for products sensitive to temperature and humidity. Warehouse mapping is not just about proper space organization; it also plays a vital role in monitoring and controlling environmental conditions, ensuring that products are kept within established parameters. In this article, we explain the importance of warehouse mapping for temperature and humidity control and how Torsa’s Borea System can be the ideal solution to meet GxP standards and protect the quality of your products.

What is warehouse mapping and why is it crucial for environmental control?

Warehouse mapping, in the context of sensitive products, involves creating a detailed plan that identifies the critical areas within the warehouse where it is necessary to control and monitor variables such as temperature and humidity. This is especially important for pharmaceutical, food, or any goods that require specific environmental conditions to maintain their quality and safety.

The goal of mapping is to ensure that all areas of the warehouse meet the required standards set by GMP and GDP regulations, providing full visibility of environmental variations in real time. Poor control of these parameters can compromise product quality, leading to economic losses and issues with current legislation.

Benefits of mapping for temperature and humidity control

Ensures compliance with GxP regulations

GxP establishes a set of rigorous standards to ensure that products are stored and transported under safe conditions. Temperature and humidity mapping ensures that all areas of the warehouse are under constant supervision, allowing companies to comply with these regulations efficiently without compromising product integrity.

Prevents degradation of sensitive products

By continuously monitoring temperature and humidity in different areas, mapping helps identify potential risk zones where environmental conditions may not be optimal. This helps prevent the degradation or loss of valuable products, such as pharmaceuticals, perishable foods, or chemicals that require precise control of storage conditions.

Identification of critical areas

Mapping allows for the identification of areas within the warehouse where stricter controls are required due to thermal fluctuations or uneven humidity levels. These critical zones are common in warehouses that lack homogeneous infrastructure or that exhibit significant differences in ventilation, sun exposure, or other external conditions.

Optimizes space planning for safe storage

Beyond the physical organization of the warehouse, mapping based on environmental control allows for optimizing the use of space according to the specific needs of each type of product. Areas with more controlled conditions can be assigned to the most sensitive products, while others can be stored in zones with less stringent control requirements, thus maximizing safety and operational efficiency.

Challenges of not conducting adequate environmental mapping

Non-compliance with regulations

Failure to adequately map environmental conditions can lead to non-compliance with GMP and GDP regulations. This could result in regulatory penalties, loss of certifications, and ultimately jeopardize the distribution of products in key markets.

Loss of quality and degradation of products

The lack of precise monitoring of temperature and humidity increases the risk of product deterioration, which can lead to returns, economic losses, and compromise the company’s reputation. This is especially critical in industries such as pharmaceuticals or food, where the margin for error is very small.

Audit risks and batch rejection

Companies that do not implement adequate control of storage conditions are more exposed to batch rejections during quality audits. This not only affects operations but also incurs additional costs and jeopardizes the supply chain.

Stages of thermal mapping

Definition of the mapping protocol

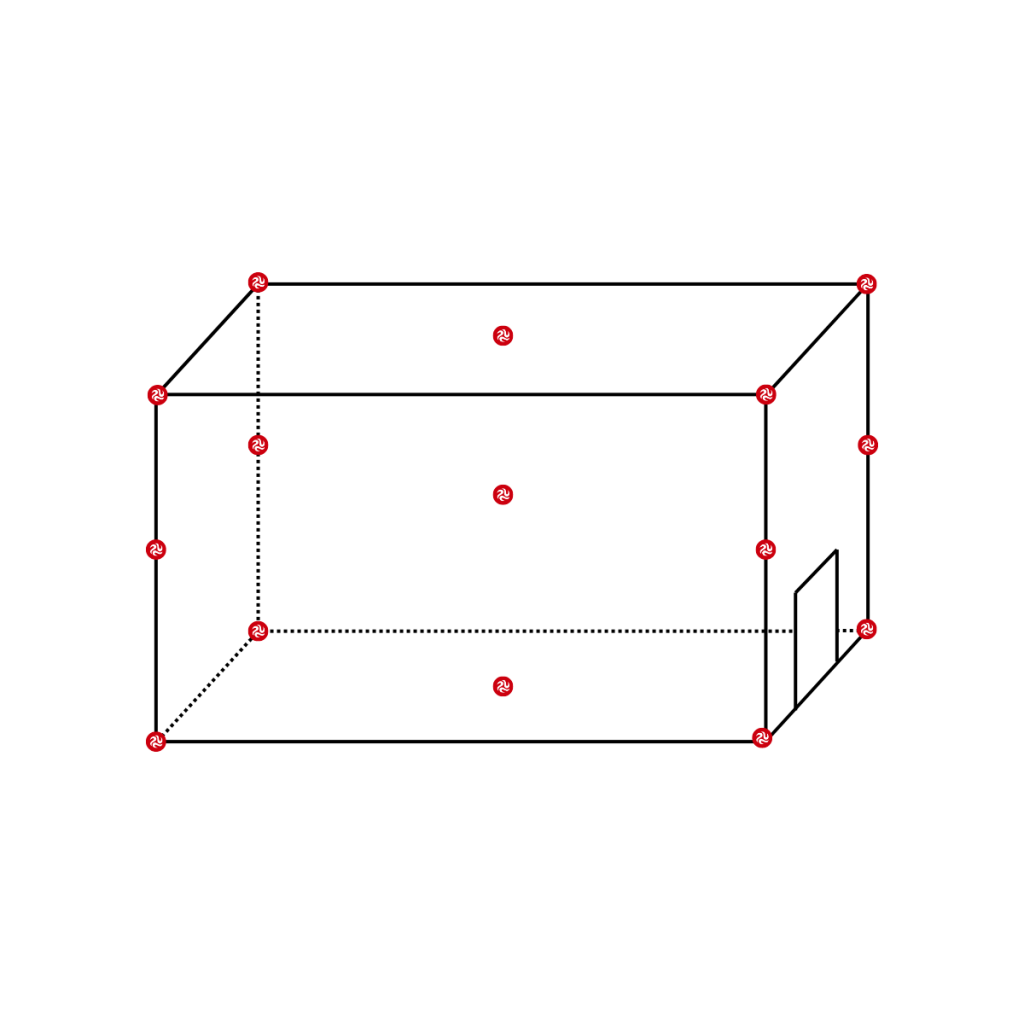

This initial stage involves establishing the criteria, objectives, and parameters of the mapping study. Critical areas to monitor are identified, and the specific conditions to be evaluated are determined.

Calibration of data loggers

It is vital to ensure that the devices capturing the data are calibrated correctly. The accuracy of the sensors is fundamental to obtaining exact results.

Definition of sensor locations

Sensors are placed at strategic points in the warehouse, such as areas near entrances, ceilings, and other critical locations, to record environmental variations.

Execution of the mapping study

The mapping is carried out over a period of 7 to 15 days. During this time, the sensors capture temperature and humidity data at different points in the warehouse. Using a system like Borea, which monitors in real time, helps reduce the time and costs associated with these studies.

Data analysis

Once the data is collected, it is analyzed to identify temperature and humidity variations that may affect the stored products.

Corrective and preventive actions (CAPA)

If problematic points are detected, corrective measures need to be implemented. It is also important to anticipate actions to prevent the recurrence of errors in the future.

Final report

The study concludes with the preparation of a detailed report certifying compliance with GxP regulations and recommendations for improving storage conditions.

Borea: Comprehensive solution for warehouse mapping for temperature and humidity control

The Borea System from Torsa is a tool specifically designed to help companies conduct environmental mappings that ensure compliance with GxP regulations, guaranteeing that stored products maintain the required quality throughout all stages of the logistics process.

Capabilities of the Borea system for environmental monitoring

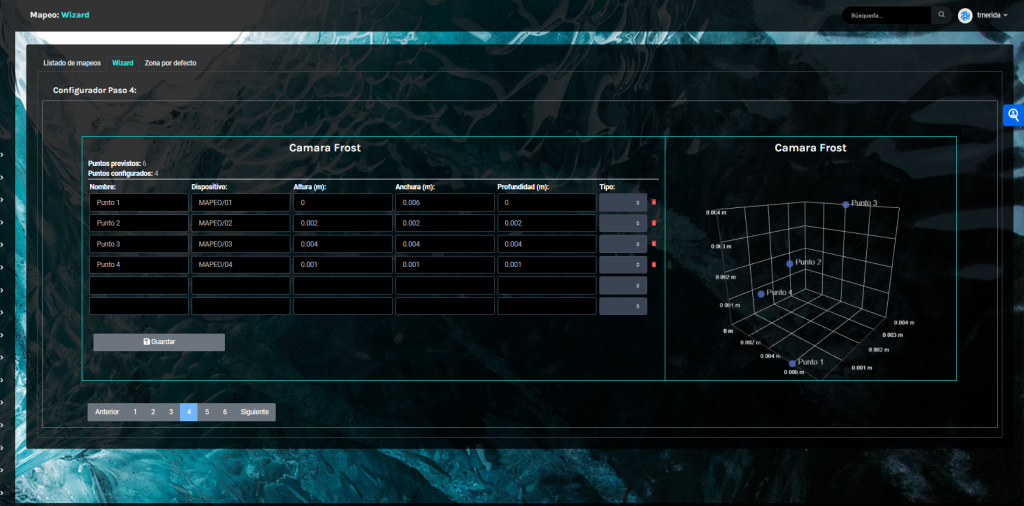

Borea offers advanced capabilities for monitoring temperature, humidity, and other critical environmental variables for the safe storage of sensitive products. Through strategically distributed sensors, the system captures real-time data from all areas of the warehouse, providing a detailed map of environmental conditions. By offering constant and automated monitoring, companies can significantly reduce operational costs and maximize the efficiency of their processes.

Reduction of operational costs

Unlike other systems, the Borea System stands out for its ability to optimize the mapping process due to its real-time and remote monitoring. Sometimes, errors such as improper installation or unforeseen incidents can cause significant problems or expenses for the company; however, Borea allows these issues to be corrected as they occur. This eliminates the need to repeat the mapping and avoids additional costs.

Since the sensors are already registered on the .torsacloud platform, data is recorded and monitored in real time, allowing for immediate detection of any anomalies and corrective action without delays. This capability not only saves time but also ensures that the process is much more agile and efficient, significantly reducing costs associated with potential errors or repetitions of the study.

For companies offering mapping services to third parties, Borea also optimizes their processes, as they can resolve issues before impacting results, allowing them to better manage both their workforce and resources. By correcting errors in real time and remotely, companies can avoid the need to repeat work, thereby improving the profitability of their operations.

Advantages of the .torsacloud software

The .torsacloud software, integrated into the Borea System, not only allows for the monitoring and recording of temperature and humidity data but also generates automated reports that comply with the strict requirements of FDA Title 21 CFR Part 11. These reports are fundamental during audits and verification processes, ensuring that operations are always aligned with international regulations.

In addition, the system allows for the configuration of customized alerts that notify staff if environmental conditions deviate from established parameters, helping to prevent issues before they affect product quality.

Flexibility and Integration

Borea easily integrates with other warehouse management systems and monitoring technologies, providing a holistic view of operations. This integration facilitates informed decision-making and enhances operational efficiency by delivering accurate, real-time data, which ultimately contributes to the reduction of operational costs.

Conclusion: Ensure the Quality of Your Products with Torsa’s Borea System

Warehouse mapping for temperature and humidity control is not just a matter of operational efficiency; it is a critical factor in ensuring that stored products comply with GxP regulations and maintain their quality. Companies that manage temperature- and humidity-sensitive products must have advanced solutions that allow them to monitor and control these variables.

The Borea System from Torsa, with its .torsacloud software, offers a comprehensive solution that ensures regulatory compliance, improves warehouse efficiency, and protects product quality. If you want to learn more about how Borea can help your company comply with GxP and optimize your logistics processes, please feel free to contact us.